What is quality controlling of no frost fin evaporator?

Answer:

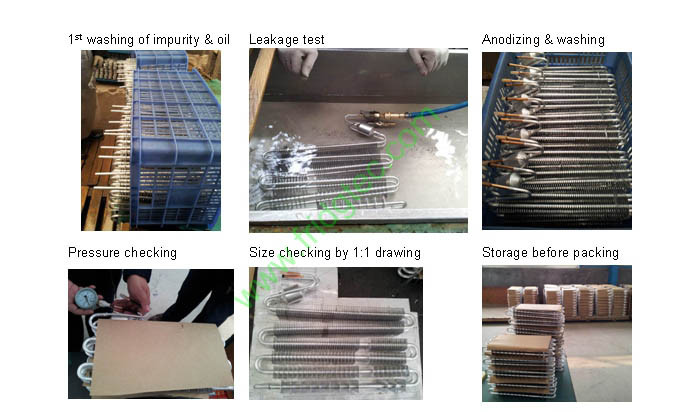

No frost fin evaporator Key Quality Control:

- Inner cleanness, washed 1st time, to get rid ofinner impurity etc, leakage testing

- Then anodized evaporator to make one anodizing film onsurface of evaporator to increase its corrosion resistance, and wash again.

- 0.1~0.15Mpa inner Nitrogen gas pressure

- Rust free liquid on end tubes, finally check leakage.

- Pressure keeping

1.Check dewell needle head with leakage ornot, the deweel gun with leakage or not.

2. Adjust pressure adjust valve, to make exitpressure within 0.6~0.8Mpa

3. Check dewell time: insert dewell needleinside cap, after pressure keeping test pressure within 0.1~0.15MPa withoutchange; if not qualified then need to adjust dewell time till good. (dewelltime: about 8s)

4. For internal installed cap, insert dewellneedle into tube, turn on swith, the dewell indication light onset; and dewellindication light off when dewell time arrives.

5. For external installed cap, the cap shallinsert 1/5 depth, dewell needle insert inside tube from 1/3 place of cap side,dewell to 0.1~0.15MPa, then pull needle and then press cap to inner tubeuickly.

- Enclosure cap leakage test:

1.Cup with 2/3 rust free liquid

2. Put the cap inside liquid over 3s, checkthere is air bubble or not; if cap hole or needle hole has air buble, then needto shake evaporator or clean it and re-test, if there is no air bubble, it isqualified piece; if it still has air bubble, then needs to take it out toreplace cap and re-make pressure keeping leakage test.