What Are the Best Metals to Plate Onto Plastic Substrates?

Plating on plastics can be achieved with various metals. Copper is the obvious choice when there is a need to enhance the electrical conductivity of the substrate. Gold or silver plating plastic can also be used to add aesthetic appeal to a plastic product. Nickel plating on plastic is also a widely implemented metal finishing industry practice.

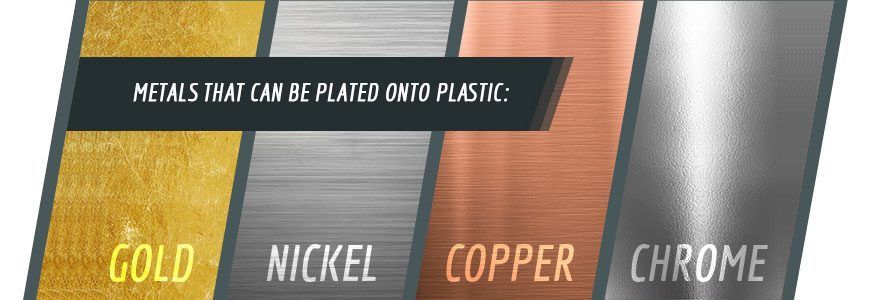

It is possible to plate a variety of metals onto plastic including:

- Gold: Gold plating plastic parts will obviously improve their appearance. Gold also offers a number of additional benefits. Gold provides protection against corrosion and is such a good conductor of electricity that it is frequently used to provide a conductive coating on electronic parts and components. Additionally, gold’s excellent heat shielding properties make it suitable for high-temperature applications.

- Nickel: Because of nickel’s bright, metallic appearance, it can serve as a suitable — and less toxic —substitute for chrome when plating plastic automotive parts. Nickel also provides protection against corrosion and wear. Alloying nickel with other metals such as tin and tungsten can increase the hardness of the nickel deposit and enhance its corrosion and wear resistance capabilities.

- Copper: Copper is perhaps best known for its excellent electrical conductivity, which is why copper plating is such as popular choice for metallizing non-conductive metal surfaces. Copper plating can also be used as a heat stop-off for masking. A major benefit of copper plating is its relatively low cost, especially when compared to precious metals such as gold and silver.

- Chrome: Despite the fact that hexavalent chromium is a known carcinogen and is listed as a hazardous air pollutant by the U.S. Environmental Protection Agency, many metal finishing shops still use chrome for automotive applications. Chrome provides a smooth surface finish, good corrosion resistance and strong aesthetic appeal. However, the chrome plating process is highly complex and can consist of as many as 30 steps. Platers that use chrome to plate on plastic are also required to adhere to strict EPA regulations.

In many plastic plating applications, it is necessary to deposit an undercoat onto the plastic substrate prior to electroplating in order to build thickness and promote coating adhesion. A process known as electroless plating is typically used to accomplish the task. Electroless plating differs from electroplating in that no electrical current is used to deposit the coating. Instead, deposition occurs via an autocatalytic chemical reaction. Nickel and copper are the two most commonly used metals for electroless plating, although techniques for gold and tin have also been developed.