Wire Shelf, Wire Basket, Semi automatic Gantry Row Welding Machine

- group name

- Customized machinery

- Min Order

- 1 piece

- model

- DN-2×150KVA

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A

- Export mode

- Export through agents & Have the independent export and import right

- update time

- Fri, 15 Nov 2019 18:42:38 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Part A: Customized Design

Customized application: for the production of wire shelf and wire basket

According to the welding requirement & the dimension of all wire shelves, we designed machine DN-2×150KVA gantry semi-automatic welding machine with 8 welding heads,.

*The design is only for reference of any steel wire products including wire shelf, wire mesh, defence guard etc, exact machine design may be adjusted and differed by customer’s different product size & shapes.

Part B:Construction of the machine

Thediameter of the steel wire: φ2.5-7mm

Dimensionof the grid: the available width is 914mm (the joint of two grids maximumwidth)

Dimensionof the grid: the available length is 720mm (the maximum length of a grid)

PART C:

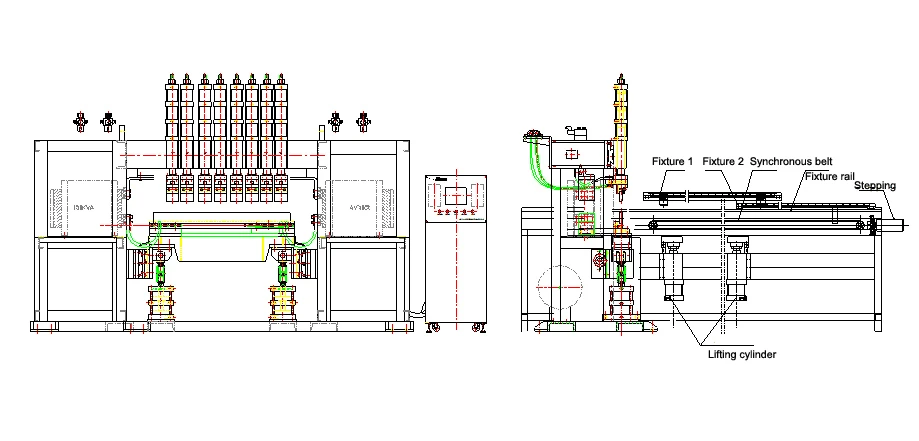

Thegeneral design sketch of machine structure:

Part D: Machine general description:

Themultiple spots welding machine is consisted of two mechanical parts: theworking part and the controlling part.

1.The machine is designed with gantry frame, there are two AC resistance weldingtransformers (150KVA) installed inside left & right cabinet, bothtransformers work 4 times simutaneously, every transformer discharges and welds1~4 welding spots, so finish the welding of one row steel wire.

2.Machine’s welding part adopts pneumatic system, eight welding cylinders areinstalled on top of the machine, and each cylinder provides welding pressureneeded for 1~4 welding spots. There are two support cylinders below themachine, they work together when welding.

3.In the front of machine working table, there is sliding device (like trolley)to put steel wire shelf on its fixture; there is location mould on trolley.

4.All performance of the machine is controlled by the PLC (Programmable LogicController), there are two resistance welding controllers equipped to control pressurization,welding, maintenance, pause time & welding current.

5.During the welding process, workers need to put the shelf frame on its fixture,place steel wires & pick finished shelf from fixture by hand; All othersteps including delivering, stepping, welding, lifting, resetting actautomatically.

7.Capacity is 2x150KVA, the voltage is 380V±10%, 50/60Hz, the pressure of thecompressed air is more than 0.6Mpa, the pressure of the cooling water is morethan 0.2Mpa.

Part E: Design advantage:

Controlledby the PLC, the welding performance is normative; it can weld multiple wireshelf products in big Lot.

Themachine adopts module of one-time pressing & electric discharging welding,it can reduce the deformation of wire shelf.

Itis suitable to any dimension shelf within the sizes, only needs to change thefixture.

Theelectricity of each cylinder is independent and can be controlled freely incertain range; it is convenient and easy to operate.

Everytime 2 welding cylinders work, each cylinder welds 2 spots simutanously, timesaving and efficiency inceasing.

Thewelding speed: 2~3 seconds/row

Themachine is controlled by the microcomputer; it can store mutiple weldingparameters for different products.

rol pressurization,welding, maintenance, pause time & welding current.5.During the welding process, workers need to put the shelf frame on its fixture,place steel wires & pick finished shelf from fixture by hand; All othersteps including delivering, stepping, welding, lifting, resetting actautomatically.

7.Capacity is 2x150KVA, the voltage is 380V±10%, 50/60Hz, the pressure of thecompressed air is more than 0.6Mpa, the pressure of the cooling water is morethan 0.2Mpa.

Part F: Main technical specifications:

The input voltage: 380±10% 50/60Hz

The rated power: 2×150KVA

The secondary voltage: 11V

The max welding current: 28.7KA

The loading duration factor: 50%

Insulation resistance of the input current to the machine body: ≥2.5MΩ

The working environment:temparture≤ 40℃,relative humidity≤90%

The pressure of the air supply: ≥0.5Mpa

The working pressure: adjustable from 100 to 4.2KN

The cooling way of the electrode: the cycled water-cooling

The production efficiency: 4~6 shelves/minute